Lamps on the industrial market:

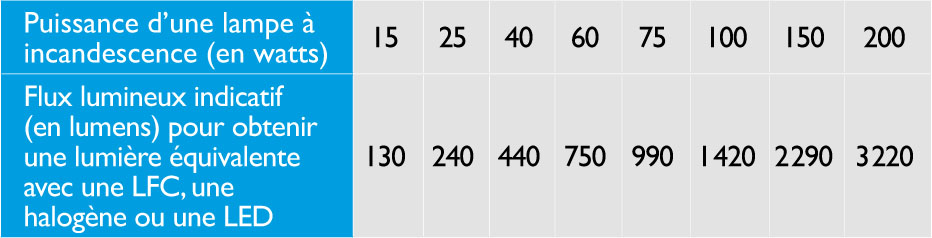

To choose an incandescent lamp, you used its power consumption, expressed in watts (W). The comparison is complicated with more efficient lamps whose luminous efficacy changes with the power. The increase in the quantity of light produced is no longer directly proportional to the increase in power.

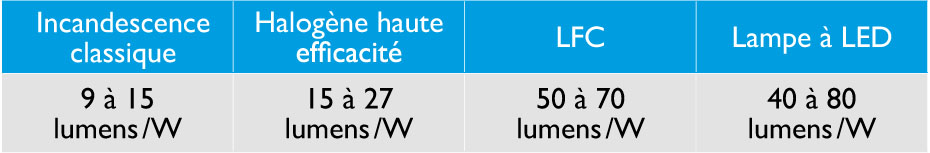

It is more judicious to be guided by the luminous flux emitted by a lamp, expressed in lumens (see table) or by the luminous efficacy, in lumens per watt (the greater the luminous efficacy, the more light the lamp emits for the same electrical consumption).

Luminous efficiency of different types of lamps:

Luminous flux equivalent to the power of an incandescent lamp

To optimize the use of light in your installations and benefit from the best possible luminous efficiency, good usage practices must be respected:

LED lamps are becoming more widespread in the industrial lighting market LED technology continues to progress: LED performance doubles every 2 years and prices decrease by 20% each year. The advantages:

There are several types of SMD LEDs offering very different powers. The SMD LED has been around for many years but due to a rather complex soldering procedure it is mainly reserved for industrial applications that require a power

This power LED technology is evolving and gaining more and more ground in the industry because these are the LEDs that offer the most light relative to the emitting surface of the LED.

This new generation of LEDs is increasingly used in industrial environments. COB LEDs are small light chips arranged side by side to form a larger LED. They have the same advantages as High Power LEDs but offer greater light output.

Our advice:

Be careful, the angle is important. The lower the angle, the more you will have a beam effect. This beam effect can have a little design side if correctly used like along a wall for example but it is totally unsuitable for main lighting.

check_circle

check_circle

Nous utilisons des cookies tiers pour améliorer votre expérience de navigation, analyser le trafic du site et personnaliser le contenu et les publicités. En savoir plus