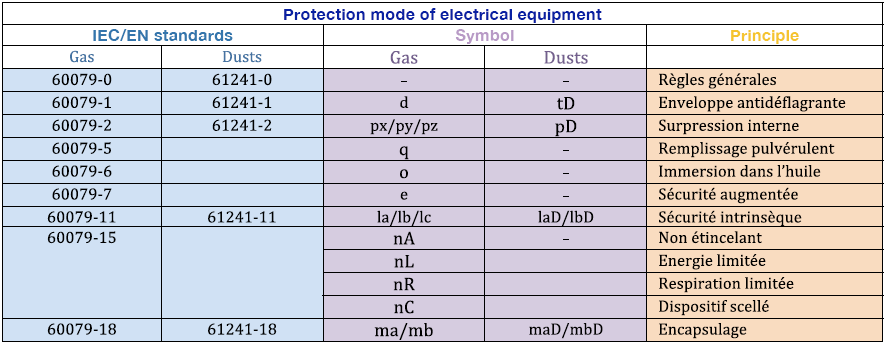

There are several types of protection recognized by the IEC (International Electrotechnical Commission) and CENELEC (European Committee for Electrotechnical Standardization). Each type of protection is symbolized by a letter that appears on the ATEX label of the equipment.

Since July 1, 2006, standards EN50014 and EN50028 have been replaced by standards EN60079 and EN61241 shown in the table below.

Several types of protection can be used on a single device. In this case, the symbols appear one after the other (e.g. Ex ib IICT4).

The most common methods of protection for ATEX lighting and low voltage switches are ATEX “d” and “e” flameproof enclosures for increased safety.

The components that generate electric arcs are enclosed in an enclosure that must fulfill three functions:

– Contain an internal explosion without permanent deformation.

– Ensure that contact cannot be transmitted to the surrounding atmosphere.

– At any external point, a temperature lower than the auto-ignition temperature of the gases present.

The standards established for the gap 'i' and the point length values (L) according to the gas group. Explosion-proof enclosures are usually made of cast aluminium or alloy (minimum IP54) and require regular and careful maintenance (lubrication of joints and torques).

Each component is designed not to generate sparks or overheat, why:

– Permissions are higher

– Terminals are specific (no gold-release)

– The casing is at least IP54, antistatic, impact resistant material (7 Nm).

Increased safety enclosures are usually made of reinforced polyester or polyamide. Cable connections must be rigorous (stripping and tightening) and the instructions for operating voltages and current must be followed. The temperature class takes into account the hottest point of the unit.

| PROTECTION TECHNIQUE | ||||

|---|---|---|---|---|

| Application | Type of protection | Marking | En/IEC Standards | |

| All applications | General requirements | - | 60079-0 | |

| Control stations, motors, fuses, switching equipment. power electronics | Fireproof envelope |  | Ex e | 60079-1 |

| Installation equipment, motors, lighting fixtures | Increased security |  | Ex d | 60079-7 |

| Measurement and control, automation technology, actuator sensors | Intrinsic safety |  | Ex i | 60079-11 |

| Switching and control cabinets, analysis equipment, computers | Pressurization |  | Ex p | 60079-2 |

| Motor or relay coils, solenoid valves | Encapsulation |  | Ex m | 60079-18 |

| Transformers, relays, control stations, magnetic contactors | Oil immersion |  | Ex o | 60079-6 |

| Capacitors, transformers | Powder filling |  | Ex q | 60079-5 |

| See above - only in zone 2 | 'Explosion-proof' | Ex n | 60079-15 | |

| For use in zone 0, 1, 2 / for use in zone 1, 2 | Dusty atmospheres | Ex t | 60079-31 | |

check_circle

check_circle

Nous utilisons des cookies tiers pour améliorer votre expérience de navigation, analyser le trafic du site et personnaliser le contenu et les publicités. En savoir plus